Billund Aquaculture and Aquapurna to start construction on new land-based shrimp farm

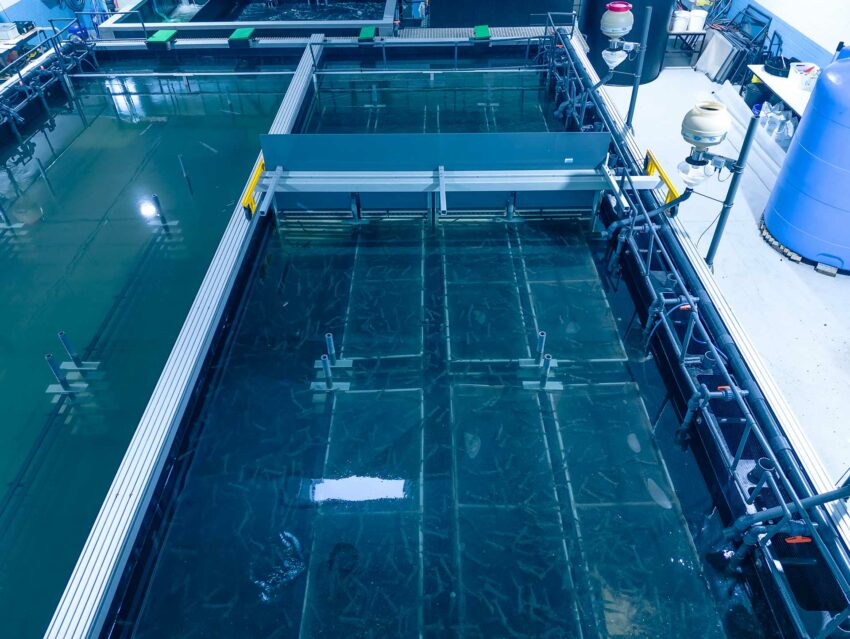

Start of ground work for the construction of the shrimp farm at the Sigmundshall plant in Wunstorf.

Billund Aquaculture and Aquapurna to start construction on new land-based shrimp farm

Having surpassed all objectives in lab-scale trials and commercial prototypes, the joint venture is preparing for large-scale production.

Construction is due to start in January 2024 of the inaugural module of Europe’s first shrimp Recirculating Aquaculture System (RAS) that is specifically designed to work at large scale and high densities. The land-based facility will be a collaborative effort between Aquapurna, a tech-company focusing on cost-efficient shrimp RAS, and Billund Aquaculture, a specialist in land-based aquaculture technology.

The facility will serve as a large-scale proof of concept, showcasing the expertise developed by both companies over the past few years. Aquapurna has been perfecting a unique shrimp farming system, while Billund Aquaculture has been providing state-of-the-art water treatment technology to the project. The two companies have teamed up a combined task force of 24 people exclusively involved in this project.

Billund Aquaculture's Chief Sales Officer, Bjarne Hald Olsen, said, "Throughout this period, we have challenged each other, our choices of technology and the pros and cons of different solutions. A lot of work has been done behind the scenes to find the most efficient setup, which has led to many internal discussions and decisions."

Aquapurna's CTO and Co-Founder Florian Gösling, commented, “The synergy between our extensive knowledge in land-based shrimp farming and Billund's track record in establishing large-scale farms for various species proved to be the ideal fusion for pioneering the first large-scale, state-of-the-art shrimp Recirculating Aquaculture System.”

Once the first farming module has proven stable operation, the farm's production capacity will increase sixfold.

Location and potential

Construction of what is expected to become the world's largest high-intensity RAS shrimp system is set to start in January 2024 at the Sigmundshall Industrial Site, located in the Hanover region, just west of the city of Wunstorf, Germany. The choice of site not only transforms a former mining area into an innovation hub but is also conveniently located close to one of Europe's major seafood consumption markets.

The joint venture expects to introduce the first shrimp larvae into the farm by the end of 2024.

This specific site offers significant potential for improvement and expansion. Six additional modules can be added, bringing the total to seven and covering an area of 30,000m² (18.000m² of which are constructible zone). According to Aquapurna's CEO David Gebhard, “If the project proves successful, we expect immediate government approval for these additional modules, significantly increasing our production capacity.”

Objectives and support

Among the main drivers behind this project are the need to address problems with poor shrimp quality and a dependence on imported shrimp. Environmental consequences of shrimp farming persist ranging from deforestation of mangrove forests to human trafficking and slavery. For that reason, the purpose of this land-based farm is to “supply the world with delicious shrimp while protecting the planet,” according to David Gebhard.

Furthermore, as this technology can be implemented anywhere, similar projects can be developed, thus helping decrease food transportation distances and reducing reliance on food imports.

German mining and agricultural giant K+S has invested significantly in scaling up Aquapurna's technology. In addition, investment has come from specialists from the food and retail industry, among others.