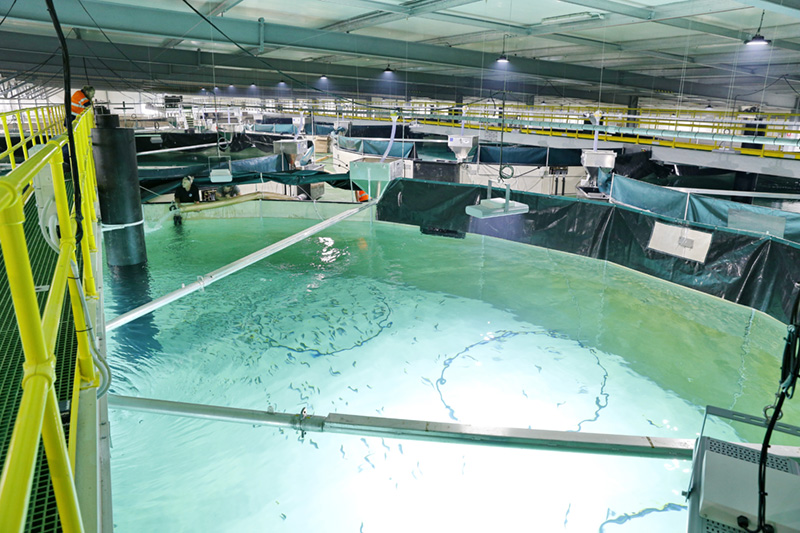

Whale Point nursery is unprecedented in so many ways. Building this gigantic but adaptable facility posed a series of challenges as it combined different cutting-edge technologies and innovations that had never been used together before. The magnitude and flexible nature of this project have helped Huon Aquaculture to produce in Tasmania the largest smolts in the entire Southern Hemisphere.

At Whale Point it is bit like in Texas, everything is bigger. Billund Aquaculture built the Whale Point nursery in 2017-2019 utilizing the largest tanks we had ever designed for smolt system (800 m3), the longest pipeline we had ever manufactured for fish transportation (1,200 m), and 10-inch grading equipment that allow the rearing of fish of over 1 kg. Nowadays, fish can be produced on demand. Using this new facility, and depending on the mode of harvest, the client can adapt their hatchery production plan based on demand. For example, they can harvest some of the biomass at smaller 250-450g and grow the remaining fish to 1000g or larger.

However, size is not important. What is most impressive with this new facility is its productive capacity. With the latest 2020 batch from Whale Point, Huon Aquaculture was able to achieve the lowest mortality rate on record with less than 0.1% even after one-week post-transfer to sea. The fish produced here are undoubtedly extremely healthy and robust.

Moreover, Australia has extremely tight environmental regulation that has pushed us to improve lots of processes. At Whale Point nursery we implemented full-flow ozone treatment system, paired with an intensive wastewater treatment system for ‘zero discharge’. Whilst the removed solids are used as fertilizer for pasture, the discharged water is re-used for salmon bathing in wellboats.

As a result, a lot of our focus has been on water consumption and reduction of discharge and this has probably been our greatest innovation so far. All of this is not the result of a single component or technology but rather part of a thought process that runs from day one to the end.

The design, construction and implementation of this absolutely state-of-the-art RAS facility has significantly helped us push the limits of aquaculture technology. And the knowledge and experienced we have gained in the process is being applied to some of Billund Aquaculture’s latest developments and projects.