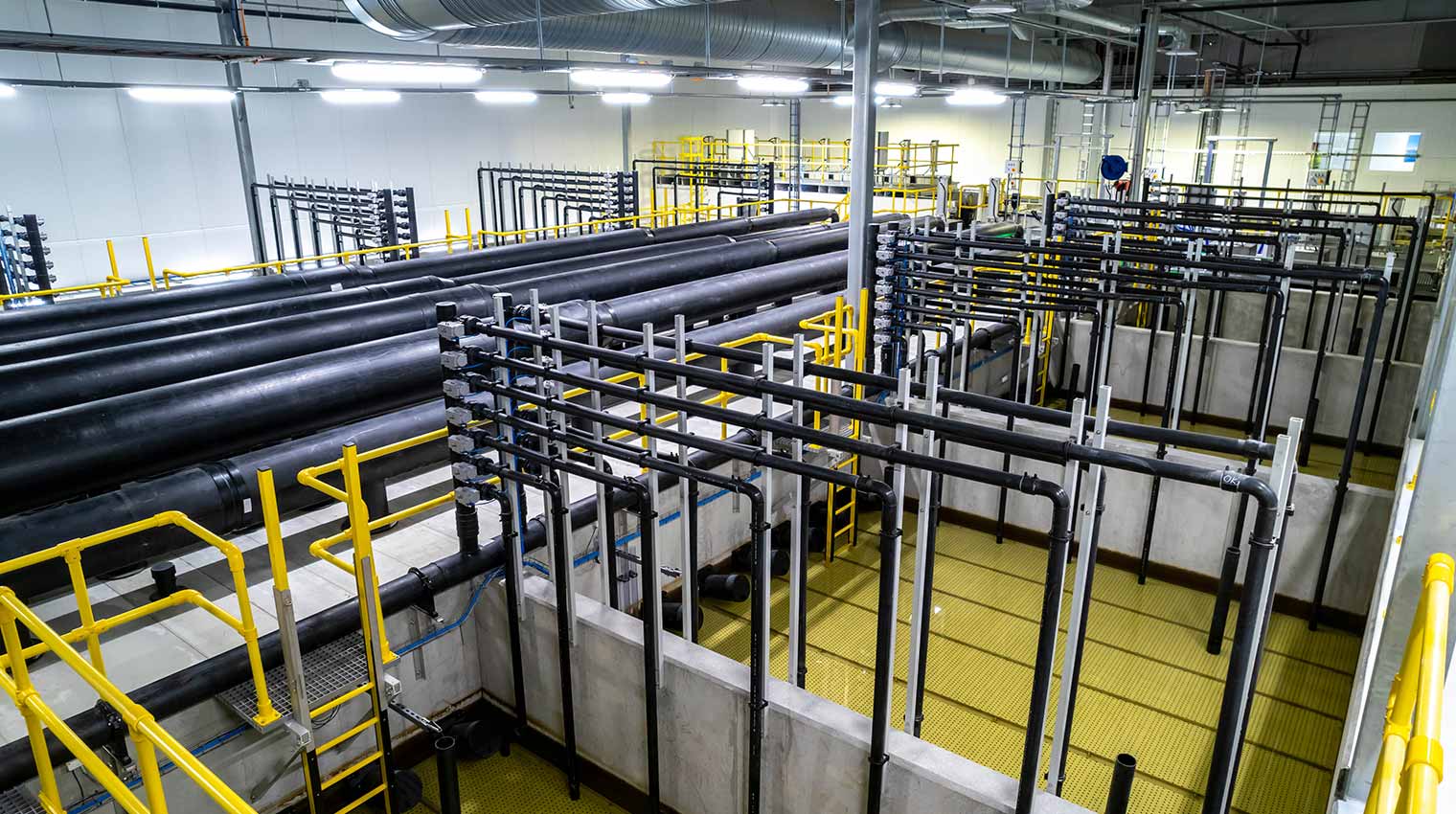

Salmar’s RAS facility located in Senja, about 200km west of Tromsø is designed to supply smolt to all of the company’s sea sites in northern Norway. The RAS consists of two units with a combined capacity of close to 29 million Atlantic salmon smolt of 120g per year.

Senja 1 was delivered in 2017 and construction of Senja 2 concluded in early 2023. Despite the relatively short span of time between the completion of both farms, there are several technological differences between the two facilities that reflect the constant pace of innovation at Billund Aquaculture. Much of the progress has come thanks to the solid and fruitful cooperation with Salmar.

Moreover, several improvements have been made at Senja 2 as part of an ongoing learning process that began with the design of Senja 1 as well as part of our in-house culture of continuous innovation.

These include a new main pump from the company Grundfos, oxygen booster systems, bio-filter inlet control valves, a passive flow system for the start-feeding tanks, the introduction of a new center screen concept and flow plates for the vacuum degasser.

The new pumps were developed for higher efficiency and lower energy consumption to suit the demand needed at large RAS facilities. Meanwhile, the oxygen booster system enables farmers to increase capacity of individual tanks within the system to meet higher requirements. All of this demonstrates how fruitful the cooperation between Billund and Salmar at the design phase has been.

There are also significant differences in the automation and programming aspects of Senja 1 and Senja 2, which is indicative of the pace of development of digitalization and automation worldwide.

Footprint optimization is also a very special feature of this land-based smolt farm. Given that construction required backfilling the ocean, this demanded a very compact, functional, and optimal design.